SG111A Sensor Characterization

The SG111A sensor will be characterized and tested against known reference sensors and calibration test gas @ 1000 PPM to determine accuracy, repeat-ability, stability and response time.

Reference board specs:

- Aretas A800016-3.0 Mainboard

- Sensiron T+RH sensor SHT31-DIS-B (+/- 0.2C +/- 2%RH)

- K30 CO2 sensor

- SG111A CO2 Sensor

- WiFi module

- Low ripple +5V DC switching power supply

Overall system setup

- 1000 PPM Calibration gas with 0.5 SLPM regulator and test fixture

- Two other K30 based reference monitors measuring ambient CO2 levels

- Cloud connected devices for concurrent analysis

- DAQ (data acquisition) polling interval ~30 seconds

Other implementation notes

- No effort was made to correct the output from the SG111A

- No commands were written to the SG111A

- Only automated output was read via UART

SG111A Sensor 1 Testing

Exposure to 1000 PPM Calibration Gas

Test procedure:

- K30 sensor exposed to 1000PPM test gas for ~90 seconds

- SG111A sensor exposed to 1000PPM test gas for ~90 seconds

- Ambient environmental tests over 14 days

Results:

K30 sensor reports ~943 PPM during the test exposure (+/- 50PPM)

SG11A sensor reports 1050-1100PPM during the test exposure (+/-100PPM)

*note there is also a fairly large ambient response difference between the two sensors

Ambient Response

Sensor response is characterized against 3 collocated reference sensors. Ambient averages of the K30 reference sensors are ~475 PPM during the reference period, whereas SG111A output is ~526 PPM. However, note that the SG111A tracks the output of the reference sensors very well and the magnitude of change and response characteristics are consistent. Output is just consistently offset by a fixed amount.

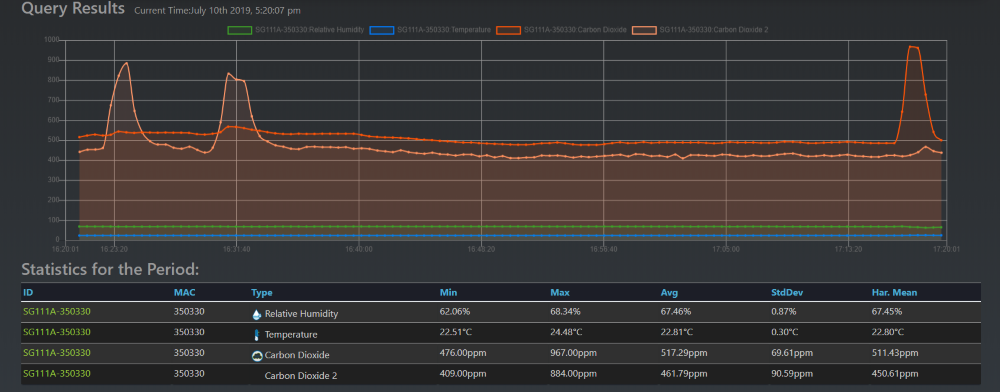

SG111A Sensor 2 Testing

Exposure to 1000 PPM Calibration Gas and Ambient Comparison

Test procedure:

- SG111A sensor exposed to 1000PPM test gas for ~90 seconds (x 2)

- K30 sensor exposed to 1000PPM for ~60 seconds

- Ambient environmental test for ~1HR

Results:

Test 1: Max concentration reported = 884 PPM

Test 2: Max concentration reported = 832 PPM

Reference Sensor Exposure: K30 reports 967 PPM

Note: SG111A Sensor 2 response is consistently ~70PPM below reference sensor

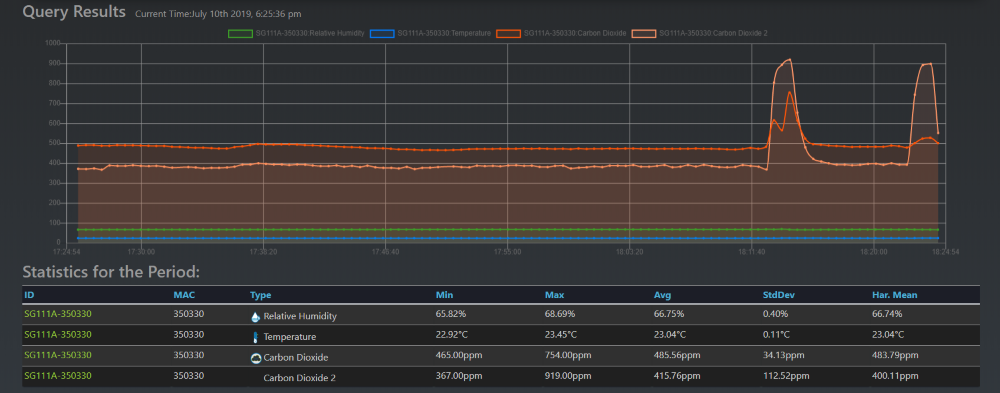

SG111A Sensor 3 Testing

Exposure to 1000 PPM Calibration Gas and Ambient Comparison

Test procedure:

- SG111A sensor exposed to 1000PPM test gas for ~90 seconds (x 2)

- Ambient environmental test for ~1 hr

Results:

*note that fluctuations on the K30 sensor CO2 output during SG111A tests are due to CO2 emitted from the port of the test fixture

Test 1: Max concentration reported = 919 PPM

Test 2: Max concentration reported = 898 PPM

Note: SG111A output consistently 90PPM below reference sensor.

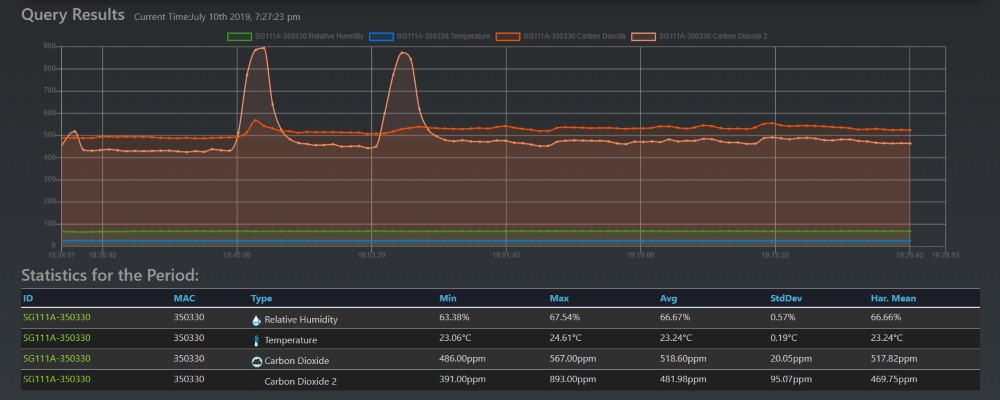

SG111A Sensor 4 Testing

Exposure to 1000 PPM Calibration Gas and Ambient Comparison

Test procedure:

- SG111A sensor exposed to 1000PPM test gas for ~90 seconds (x 2)

- Ambient environmental test for ~1 hr

Results:

Test 1: Max concentration reported = 893 PPM

Test 2: Max concentration reported = 872 PPM

Note: SG111A output consistently ~60PPM below reference sensor.

Additional Notes

During the 14 day test period on the A800016 test board with K30 sensor attached, the SG111A tracked very well with the CO2 sensor outputs of the 3 reference sensors in the test environment. Actual average PPM output through the period was 547PPM whereas the reference sensors exhibited averages of 438PPM, 454PPM and 478PPM. However, the SG111A followed the output curves of the reference sensors fairly perfectly (meaning response times and magnitude of change were similar to the reference units).

Given the consistency and repeat-ability of the SG111A sensor, and the consistent offset during bump testing, it may be worth investigating performing a baseline offset / calibration function in the host processor firmware to help true up the readings from the sensor.

0 Comments