Differential Pressure Monitoring

*may not be exactly as shown

Quick Features

-

+/- 50Pa Differential Pressure or

+/- 125Pa Differential Pressure or

+/- 500Pa Differential Pressure - Wireless Options Available

- Flexible Power Options (DC, AC, USB)

- Optional Display

- Optional Audible Alarm

- Configurable reporting interval, alarm, etc

- Customized Options Available

- Cloud and Edge Compatible / Alerts / Text Alerts / Charting

- USB Programmable (depending on mainboard)

Description

A differential pressure monitor measures the differential pressure between two zones. A positive differential pressure means one room has greater pressure than the adjacent room and air would typically want to flow OUT of the greater pressure area. A negative differential pressure, means one room has less pressure than the adjacent room and air would typically want to flow IN to the lower pressure area.

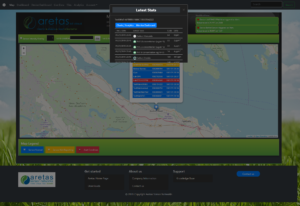

Remote Differential Pressure Monitoring

You can monitor differential pressure from anywhere in the world. Login to your Edge device or Cloud account wherever you are in the world and see the current differential pressure as well as all the historical data.

Applications

Hospitals

Positive or Negative Pressure Isolation Rooms, Operating Rooms and any other room requiring differential pressure monitoring and alarm

Pharmacy

Positive or Negative Pressure Isolation Rooms, Operating Rooms and any other room requiring differential pressure monitoring and alarm

Manufacturing / Clean Rooms

Maintaining positive pressure in a manufacturing clean room is critical for various reasons, including certification.

Labs

Many labs require continuous fresh air intake and exhaust, or have high capacity exhaust systems that can create significant differential pressure issues.

Datacenters / Containers

Server rooms, datacenters and containers all require reliable ventilation to prevent servers from overheating. Datacenters also often require positive pressure to keep dust and contaminants out.

Electrical Rooms / Industrial Control Rooms

Electrical rooms in an Industrial setting, such as a sawmill, granary or food manufacturing facility, where high voltage panels are installed, need to have positive pressure to keep out combustible dust and contaminants.

Wireless Options

- XBee 2.4GHz (Low and High Power)

- XBee 900MHz

- WiFI 2.4GHz

- SwarmBee

Sensor Specifications

- Measurement Range in Pascal -50 – +50 Pa

- Accuracy ± 0.1 Pa

- Operating temperature range: -20 to 80 °C

- Operating humidity: 0 to 85% RH

- Response time: 1 to 2 ms

- Additional ranges:

- +/- 125Pa

- +/- 500Pa

Power Options

- DC Power Adapter

- 24VAC

- USB Power

Software Options

Access your device data anywhere, any time. Get Alerts, Dashboards, Analytics, Live Data and more.

You can run IoT Gateway v1 with Aretas IoT Cloud or on its own (using the built-in reporting and data storage).

The Aretas Sensor Grapher is a local charting utility that requires a USB adapter and a PC with Java installed.

Additional Sensor Options

- Temperature and Relative Humidity

- Barometric Pressure (kPa)

- Pitot Airspeed

- Electrostatic Airflow

- Contact us for more options

Contact Us By Email:

Contact us now for a quote or request a custom sensor build for your special requirements

[pirate_forms]